Sanitization System Application

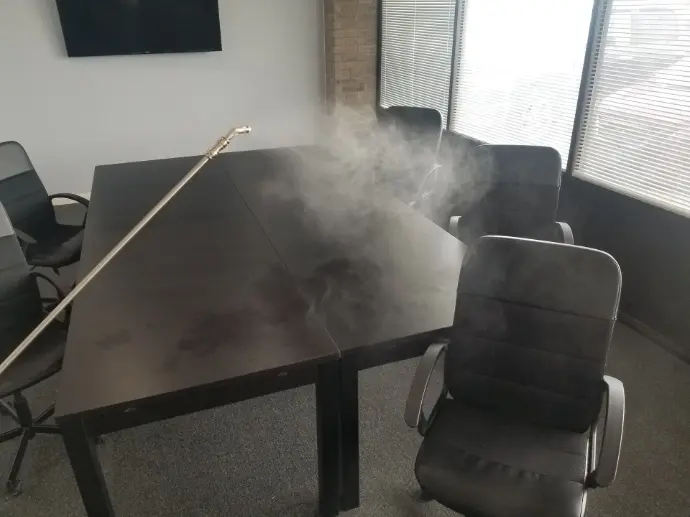

With a recent, global pandemic in the rearview mirror, the importance of sanitization has never been clearer! Who needs to scrub when a sanitizing mist can do the work for you?

Misting systems can be used for sanitation applications in various settings, offering several advantages:

1. Disinfection and Deodorization:

- Principle: Fine mist droplets can carry disinfectants or deodorizing agents to effectively cover surfaces and neutralize odors.

- Applications:

- Waste Treatment: Disinfecting and deodorizing areas in solid and liquid waste treatment plants, sewage treatment facilities, and landfills.

- Livestock Farms: Controlling odors and reducing the spread of pathogens in poultry and livestock facilities.

- Industrial Settings: Sanitizing equipment, work surfaces, and the surrounding environment in food processing, pharmaceutical, and other industries.

2. Dust Suppression:

- Principle: Fine mist droplets can bind to dust particles, making them heavier and causing them to settle.

- Applications:

- Mining and Quarries: Suppressing dust in open-pit mines, quarries, and other dusty environments to improve air quality and worker safety.

- Construction Sites: Reducing dust generated during demolition, excavation, and other construction activities.

- Agricultural Settings: Controlling dust in grain storage facilities and during harvesting operations.

3. Cooling and Humidification:

- Principle: While primarily used for cooling, misting can also help maintain appropriate humidity levels, which can indirectly contribute to a cleaner environment.

- Applications:

- Industrial Settings: Providing a more comfortable and productive work environment in hot and dusty conditions.

- Livestock Farms: Improving air quality and reducing stress in livestock by providing a cooler and more humid environment.

Key Considerations:

- Disinfectant Selection: Choose disinfectants appropriate for the specific application and target pathogens.

- Misting System Design: Optimize mist droplet size and distribution for effective coverage and minimal waste.

- Safety: Ensure proper safety measures are in place, including personal protective equipment (PPE) for workers and appropriate ventilation.

- Environmental Impact: Consider the environmental impact of the disinfectants and the potential for water waste.

Note: The effectiveness of misting for sanitation will depend on various factors, including the specific application, the chosen disinfectant or deodorizer, the design and operation of the misting system, and environmental conditions.

Disclaimer: This information is for general knowledge and informational purposes only and does not constitute professional advice. Always consult with relevant experts and follow applicable safety guidelines when implementing misting systems for sanitation.

Sanitization Booth for Entrance

- Sanitization Booth

- Walk in

- Automatic

- 360 Degree Spray

- Compatible with most sanitizers in the market

- Produces Ultra Fine Mist

- High-Performance Mist Pump

- 110v AC, 2 Amps

- Cyclic Timer (Range: 2 Secs - 12 Mins)

- 15 Gallon Reservoir

- 50ft Flexible Tubing - 1/4''

- Complete 2 Nozzle Mist Kit

Sanitization System for Shopping Cart

- Ready to use Shopping Cart System

- Easy to use

- 360 Degree Sanitization

- Stainless Steel Misting Nozzles

- 250 PSI Misting Pump

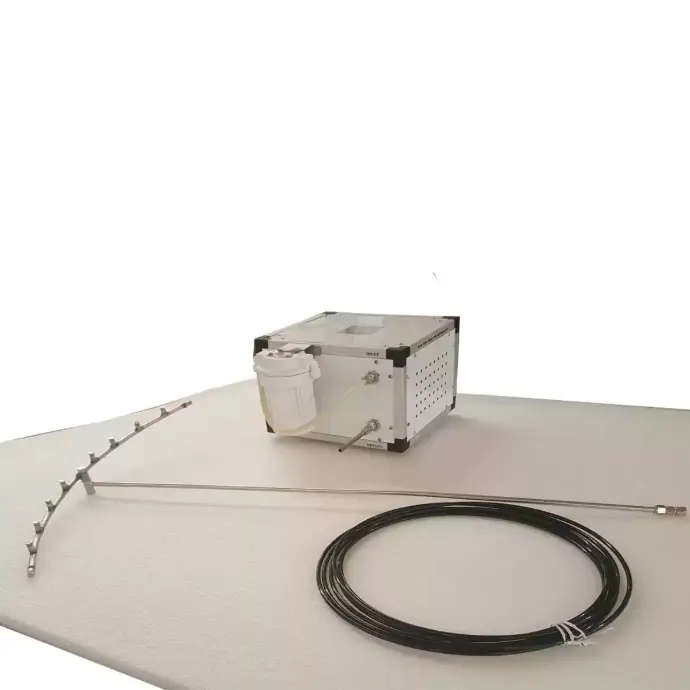

Outdoor Sanitization Misting System

- Humidification and Sanitization Arc with 10/24 Threads

- 10 Nozzles System

- 250 PSI Misting Pump with Cyclic Timer

- Stainless Steel Misting Nozzles

- Hook the Misting Pump to your Garden hose, install the Arc in a convenient location, and start the system.

Dust Control Mister | Fog Cannon

Fog Cannon - Construction Dust Control

- Mistcooling Dust Mister Fog Cannon can be used for varied applications because of its high-speed motor with 3470 rpm, 15 hp.

- The fan is equipped with 2 stainless steel rings, with a total of 36 nozzles, spraying at 182 psi to give the fine mist spray.

- Ideal for Winterized Sanitization, Dust Suppression, Recycler dumps, and Curing Concrete in the large construction areas

Because of its oscillation of 180 degrees, the dust control mister can offer a wider area of dust suppression than other conventional misting fans.

- Cover Area (sq. foot) : 30140

- Jet Distance without wind (M): 30

Dust Fan Application:

- Ideal for construction sites

- Applications such as Demolition, Material Handling, Coal Handling, Biomass, Environmental Remediation, Fly Ash Handling, Landfill Mining, Quarrying, Recycling, Recycle, Scrap, Steel, Slag, Waste Transfer

- With a mobile wheel carriage exclusively engineered to suppress dust in industrial facilities.

- It has 30 ultra-fine misting nozzles that give off 5 micron-sized water droplets that suppress dust without wetting your facility, equipment, and inventory.

- Portable.

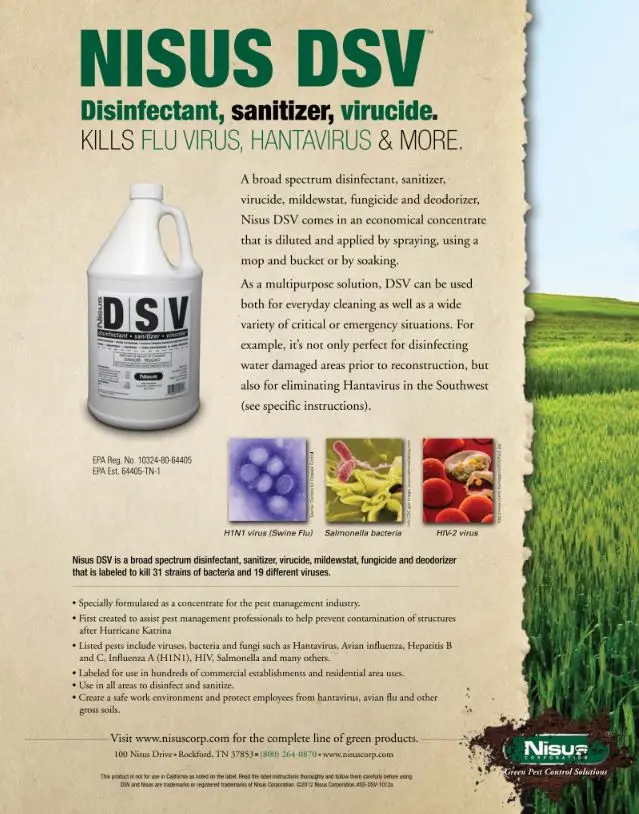

Disinfectant Sanitizer Virucide - Nisus DSV™ (1 Gallon)

- Kills harmful germs, bacteria, fungi, and viruses

- Prevents and eliminates mildew

- Disinfects hepatitis, hantavirus, avian flu, HIV, and more

- One gallon of concentrate makes 64 gallons of solution

- DSV can be used anytime you need to clean and disinfect a compromised environment. For example, use it in the aftermath of a flood to control contamination and disease-breeding conditions.

Misting Tent Sanitation System

- 10’ x 10’ Tent or 10’ x 20’ Tent

- With Tank for your Sanitizer

- Misting Pump Cyclic Timer

- Fully Automated

- Stainless Steel Misting Nozzles

*Note: 2 Mistcooling 8in x 8in branding logo on the tent corners.

**Additional shipping charges may apply. Mistcooling.com covers up to $ 100 for shipping costs. Please refer to our shipping policy.