Dust Control Application

Dust control applications vary widely depending on the source and severity of the dust issue. Here are some common applications:

1. Construction Sites:

- Soil Stabilization: Applying dust suppressants like calcium chloride or polymers to stabilize loose soil and prevent wind erosion.

- Road Construction: Controlling dust on unpaved roads and during construction activities.

- Demolition: Minimizing dust generated during demolition and debris removal.

2. Industrial Settings:

- Mining Operations: Controlling dust from mining activities, including hauling roads, stockpiles, and processing plants.

- Manufacturing: Suppressing dust in various manufacturing processes, such as grinding, milling, and material handling.

- Warehouses: Reducing dust in warehouses to improve air quality and protect stored goods.

3. Agriculture:

- Crop Dusting: Controlling dust on farm roads, in fields, and around livestock areas.

- Livestock Operations: Reducing dust in barns and around feedlots to improve animal health and worker safety.

4. Residential Areas:

- Landscaping: Controlling dust from landscaping activities, such as mowing, trimming, and leaf blowing.

- Driveways: Suppressing dust on gravel driveways.

5. Other Applications:

- Sports Fields: Controlling dust on sports fields, such as baseball diamonds and soccer fields.

- Trails and Pathways: Reducing dust on hiking and biking trails.

Methods of Dust Control:

- Chemical Treatments: Applying dust suppressants like calcium chloride, magnesium chloride, polymers, and surfactants.

- Physical Barriers: Using windbreaks, screens, and barriers to block wind and reduce dust dispersion.

- Water Application: Using sprinklers, foggers, and misters to suppress dust with water.

- Vacuuming: Using industrial vacuums to collect dust from surfaces.

- Plantings: Planting vegetation to stabilize soil and reduce wind erosion.

Choosing the Right Dust Control Method:

The most effective dust control method depends on several factors, including:

- Source of Dust: Identifying the source of dust is crucial for selecting the appropriate control method.

- Severity of Dust: The severity of the dust problem will determine the level of control required.

- Environmental Considerations: Choosing environmentally friendly methods is important, especially in sensitive areas.

- Cost-Effectiveness: Evaluating the cost-effectiveness of different methods is essential.

By carefully considering these factors, you can choose the most effective and appropriate dust control application for your specific needs

Dust Control Ring

FEATURES/SPECS: Instantly creates mist curtain to contain dust particles 3/8” rigid 316 stainless-steel ring 12/24” threaded misting nozzles risers 1/8” NPTF Inlet Stainless-Steel Orifice Mister Nozzles Optional filter and inlet hose Optional multi-zone manifolds Works well with mid and high-pressure pumps Lifetime warranty | SYSTEM INCLUDES: Stainless-steel orifice mist nozzles Stainless-steel mist ring Pre-threaded risers | |

Ring 3/8” rig 316 stainless-steel ring Lifetime guarantee, works well with MP and HP | Nozzles Stainless-Steel mist Orifice nozzles | Risers Pre-threaded standard 12/24” nozzle risers |

SOURCES: www.mistcooling.com |

DUST CONTROL RING

Outfitted with high quality, Stainless Steel Orifice Atomizing Misting Nozzles, the Dust Control Misting Ring is the most effective, efficient system available for quick dust control system management at industrial/construction sites. Efficiently contains dust by absorbing particles in fine mist water droplets. Lifetime Guarantee. 3/8” Rigid 316 Stainless Steel, 12/24” misting nozzles risers, 1/8” NPTF Inlet, Stainless Steel Orifice Cool Mister Heads. Customizable.

SITUATION You are gunning for the completion deadline at the construction site. But, dust is ‘clouding’ the operation and choking your workers. There must be a way to contain the dust to finish the job by the deadline.

SOLUTION Our Dust Control Ring creates a virtual yet powerful curtain for dust particle containment and suppression. The Stainless Steel Orifice Atomizing Dust Suppression Nozzles deployed on this Ring deliver millions of tiny mist droplets per minute, suppressing the dust found in the air quickly and efficiently while keeping the surroundings cool. This ring is ideal for industrial dust control systems at industrial locations, construction sites, and radial stackers. Bottom line is, you get to complete your project on time!

To show our confidence in our dust control spray ring, we provide you with a Lifetime Warranty. Rest assured, your investment is safe.

ADVANTAGES

- Instantly works by creating a mist curtain cooling acting as an air dust collector to contain dust particles

- Durable construction is also rust resistant

- Adjustable nozzles focus on areas where dust control is needed

- Lifetime Warranty

RING COMPONENTS

- 3/8” Rigid 316 Stainless Steel

- 12/24” mister spray heads Risers

- 1/8” NPTF Inlet

- Nickel Plated Brass Mister Nozzles with Stainless Steel Orifices with standard 12/24” threading

OPTIONAL

- Filter

- Inlet hose

- Multizone Manifolds

- Booster Pumps

FEATURES

- Works well with Mid Pressure Misting Pump and High Pressure Mister Pumps

- Additional shipping charges may apply for larger ring

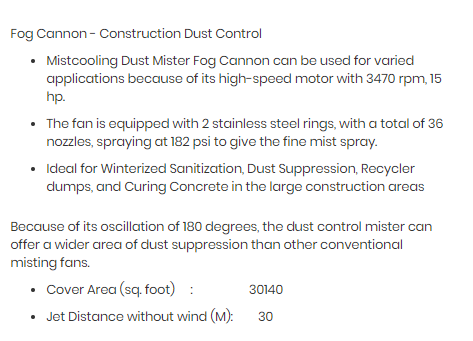

Fog Cannon

A dust control cannon is a specialized piece of equipment used to suppress dust in various outdoor environments. Here's how it works:

How it works:

- Atomization: Dust control cannons use high-pressure water nozzles to atomize water into a fine mist. This creates a large surface area of water droplets.

- Projection: Powerful fans propel this fine mist over a considerable distance, often reaching distances of 100 feet or more.

- Dust Suppression:

- Impact: The water droplets collide with dust particles, increasing their weight and causing them to fall to the ground.

- Humidity: The fine mist also increases the humidity in the air, which can help to suppress dust by reducing the drying and mobilization of soil particles.

Applications:

Dust control cannons are used in a variety of applications, including:

- Construction Sites: Suppressing dust from excavation, demolition, and material handling activities.

- Mining Operations: Controlling dust from open-pit mines, haul roads, and processing plants.

- Agriculture: Reducing dust in fields, around livestock areas, and on farm roads.

- Industrial Settings: Controlling dust in industrial processes, such as material handling and processing.

- Waste Management: Suppressing dust at landfills and recycling facilities.

Benefits:

- Effective Dust Suppression: Can effectively suppress dust over large areas.

- Versatility: Can be used in a variety of applications and environments.

- Relatively Low Maintenance: Generally require minimal maintenance.

Dust Control Misting System

Completely Customizable Portable misting system for dust suppression at construction sites or mining dust suppression. Also, can also be used for Odor Control System Misting for dump sites, sewage plants, and recycling plants. Includes 1500psi High-Pressure Misting Pump, 36” outdoor-rated high-velocity Industrial Misting Fan, Generator, Dual Stainless-Steel Misting System Misting Rings with Lifetime Guarantee, Scale-Free and Sediment Filters, Anti-Drip Stainless-Steel Misting Nozzles, Trailer with all-terrain wheels, Tank Drain, and all other required parts.

SITUATION Construction of a new building is, as usual, kicking up a lot of dust into the area, and as usual, your workers are choking on it and having a hard time working at the same time. It would be nice not to deal with this problem, but you don’t know how to solve it.

SOLUTION Our Dust Control Industrial Misting System Trailer for Commercial and Industrial Misting Systems Application will help you keep your construction site dust suppressed, so that everyone can do their job without the constant irritation of dust in the air. The Dust Suppression Nozzles on the system attach to the dust particles floating in the air and contain them so they do not float around and are weighted to fall to the ground. Your employees are no longer continually choking on dust and are focusing on their tasks. It might even save time by eliminating the disturbances dust can create.

ADVANTAGES

- Large capacity tanks eliminate the need for immediate refills

- Industrial Outdoor Fans are durable and safe to use; it will not cause a problem if wind direction changes push mist toward Fan Motor, 24”-36” Fan options, multiple Fan options

- Dual Stainless-Steel Mist Rings are Lifetime Guaranteed

- Durable, 1500psi High-Pressure Mister Pump is an industry leader

- Scale-free and Sediment Filters keep the Misting Nozzles free of clogs

- Anti-Drip Water Misting Nozzles feature produces no residual moister to create mud puddles in and about application area

- Stainless-Steel High Pressure Misting Nozzles construction resists corrosion

- Tank Drain makes it easy to release water and place into storage

- Convenient Generator included to run the Commercial Mister System

- Dust Control Misting System Trailer is sturdy and fitted with all-terrain wheels for easier placement

- System is flexible; it can be used for Odor Abatement of dump sites, sewage plants, waste treatment plants, large-scale agriculture uses like poultry houses and hog pens, processing plants, and anywhere you can place the Odor Control System trailer to eliminate odors

- System is customizable

BASE COMPONENTS AND SPECS

- 300 Gallon Tanks = a total of 600 gallons capacity

- 36” high-velocity outdoor-rated Industrial grade Fans with OSHA-approved Grills

- Dual 3/8” Rigid 316 Stainless-Steel Mist Rings with 10/24” pre-threaded nozzle slots, will not rust and are lifetime guaranteed

- 1500psi Tri-plex piston High Pressure Misting System Pump, direct drive on 56C NEMA frame motor, flow rate adjustable with PRV, built-in water cut off, solenoid, thermal safety switch, pressure gauge, and pressure bypass all in weather proof Enclosure, high Amp On/Off Switch, Max 1500psi output, quiet operation, can take inlet water from external tank, fan cooled motor with H-class rating, 1 GPM

- 20” Scale-Free Filter

- 20” Sediment Filter

- 24ct 0.008” Anti-Drip Stainless-Steel Misting Nozzles with rust resistant impeller pin, and 10/24” Threading

- Tank Drain

- Generator